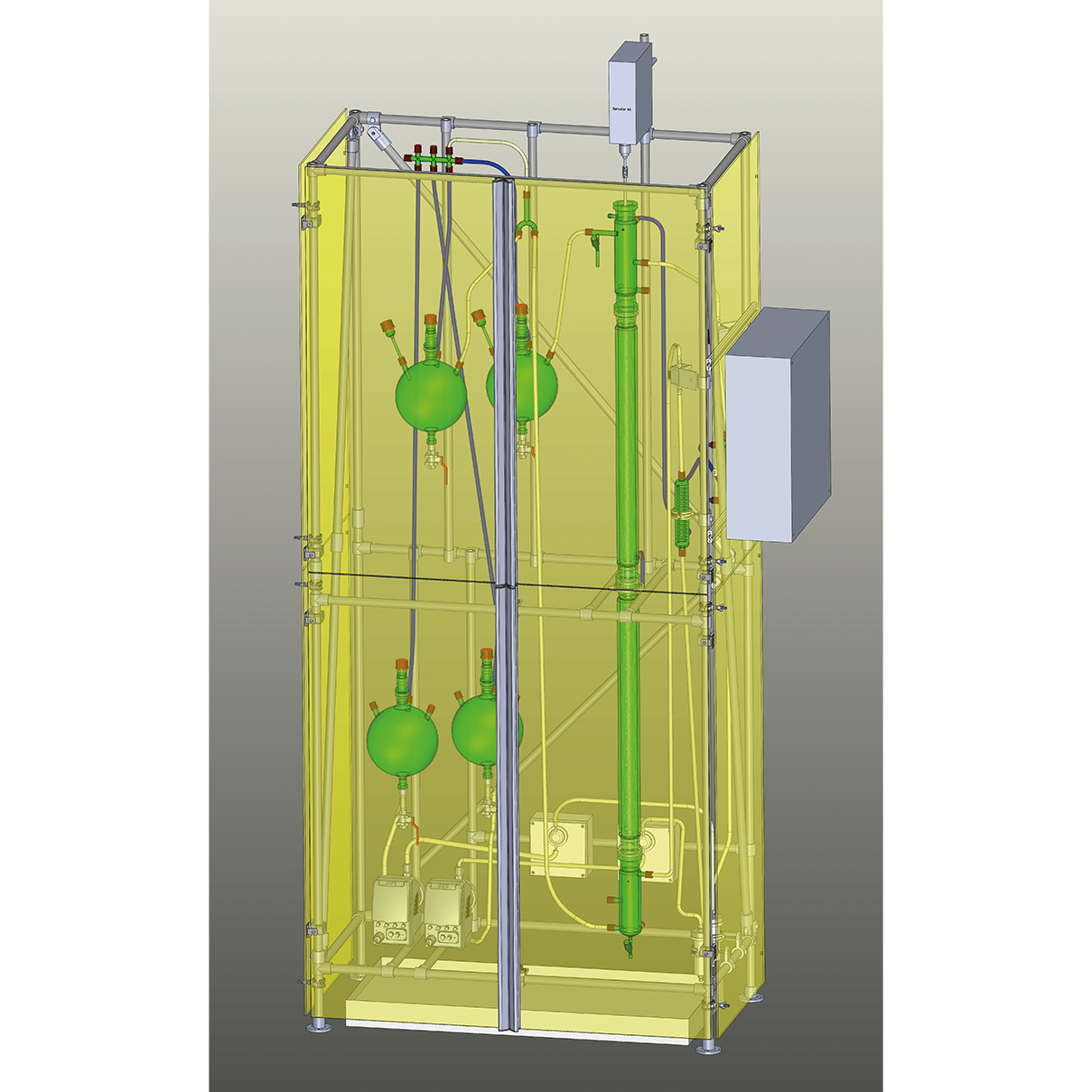

Liquid/Liquid Extractor DN20, DN50

The unit for the liquid/liquid extraction operates in a counter-current flow and is designed as a pulsed column with sieve trays and packing material alternatively. The working principle of this unit is based on the fact, that the two liquid phases are pressed through the holes of each sieve tray or through the packing respectively, forced by the used pulsation, thus one phase will be dispersed into the other.

The large contact surface which will be formed by this specific design, makes the product exchange between the two phases highly efficient.

During the return travel of the pulsator, the drops previously dispersed are agglomerating into a homogeneous phase.

The light phase will be fed into the system at the lower end of the column, while the heavy phase is entering the tower at the upper end.

Due to the gravitation, supported by the said pulsation, both phases are passing the column in countercurrent way and are withdrawn at the opposite ends.

The feed streams are controlled by two adjustable feed pumps. The product withdrawal is managed by two overflow systems, whereby the adjustable height of the heavy phase discharge line is controlling the location of the main phase boundary inside the column. This allows the operator’s choice, whether the heavy or the light phase should be used as the dispersed phase.

The Pulsed Extraction unit is suitable for mixtures with short settling periods (e.g. water – acetone – toluene, water – acetic acid – iso-propylether etc.).

ILUDEST® Liquid-Liquid Stirred Extraction System DN50

complete with Controller, Supporting Structure, Safety Screens and Collection Trough

What can we do for you?

If you want more specific information regarding this product, please contact our Sales team.

We are happy to assist you.

Features & Benefits

- Design: Counter-current flow pulsed column with alternating sieve trays and packing material.

- Working principle: Pulsation forces one liquid phase to disperse into the other, creating a large contact surface for efficient mass transfer.

- Flow direction: Light phase enters at the bottom, heavy phase at the top. Both phases flow counter-currently due to gravity and pulsation.

- Feed and product control: Adjustable pumps for feed streams, overflow systems for product withdrawal, adjustable heavy phase discharge height allows choosing the dispersed phase.

- Applications: Suitable for mixtures with short settling times.